Yard management system

Yard management system QTIR allows you to efficiently control the movement of vehicles in your area. You get an accurate and constantly updated overview of where and in what condition each vehicle is. Quickly guiding vehicles to the check-in position and simplifying communication with drivers will bring the expected time and cost savings as soon as the system is operational.

This is not a box solution. The complete operation is analyzed before the system is deployed in your company. The system is then adjusted according to your needs and expectations.

QTIR is integrated with SAP, ABRA, NAVISION and other systems. Thanks to this information, we get the shipment data into our system without the need to manually enter it again.

The system records all relevant data throughout the check-in process, from time stamps to various checklists. These serve as a basis for process optimization.

Registration

The first and one of the most important elements of any yard management system is the registration, which provides us with accurate information about the shipment and also confirms that the shipment has arrived at the premises and is ready for clearance (loading or unloading).

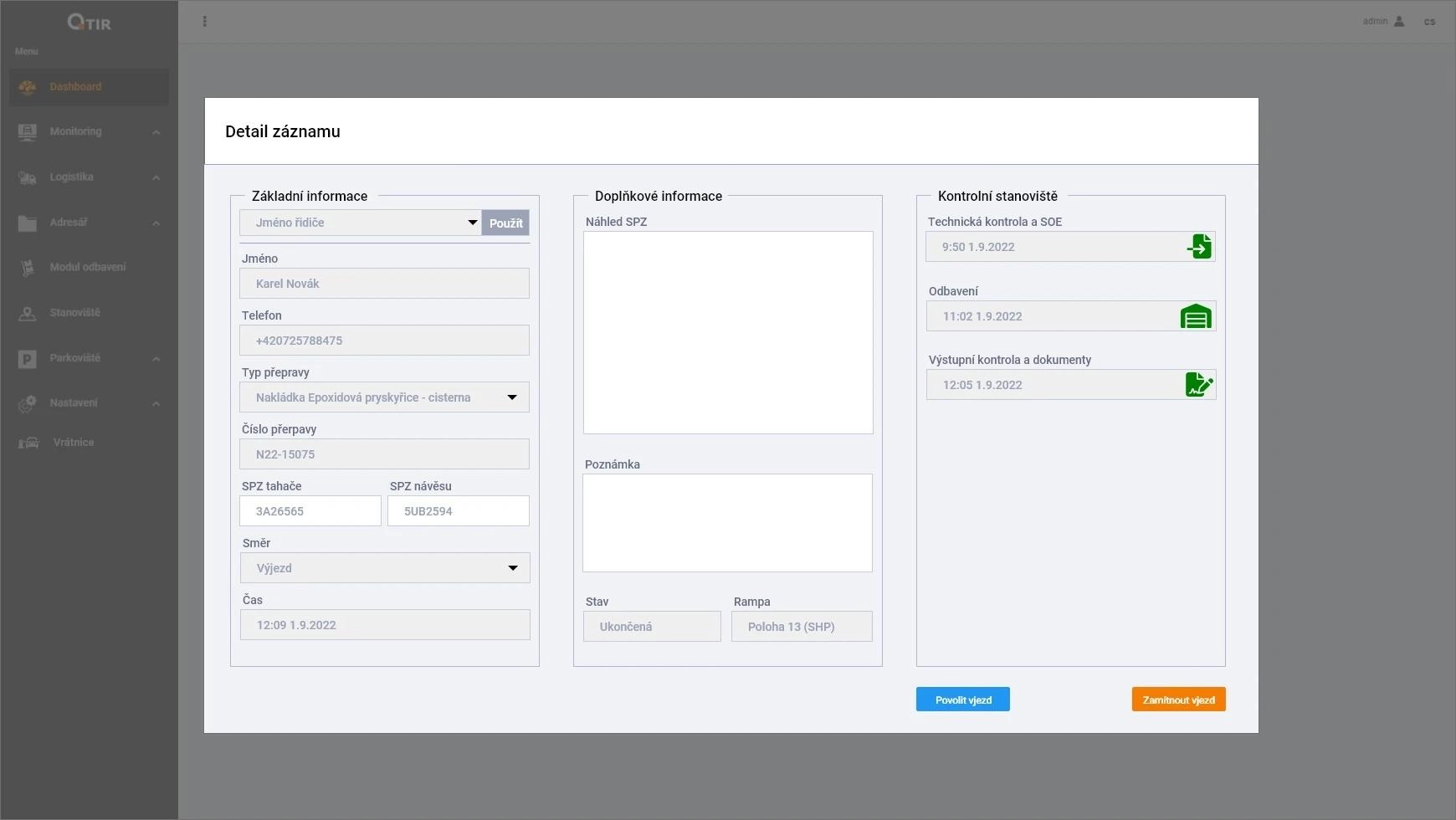

Registration is usually used to obtain basic information about the shipment, i.e. cargo, vehicle and driver. Typically, this includes information such as the transport id, shipment number, order number, type of clearance loading/unloading, the registration number of the tractor or semi-trailer and, last but not least, the name and telephone number of the driver or other optional information that is appropriate for the type of transport.

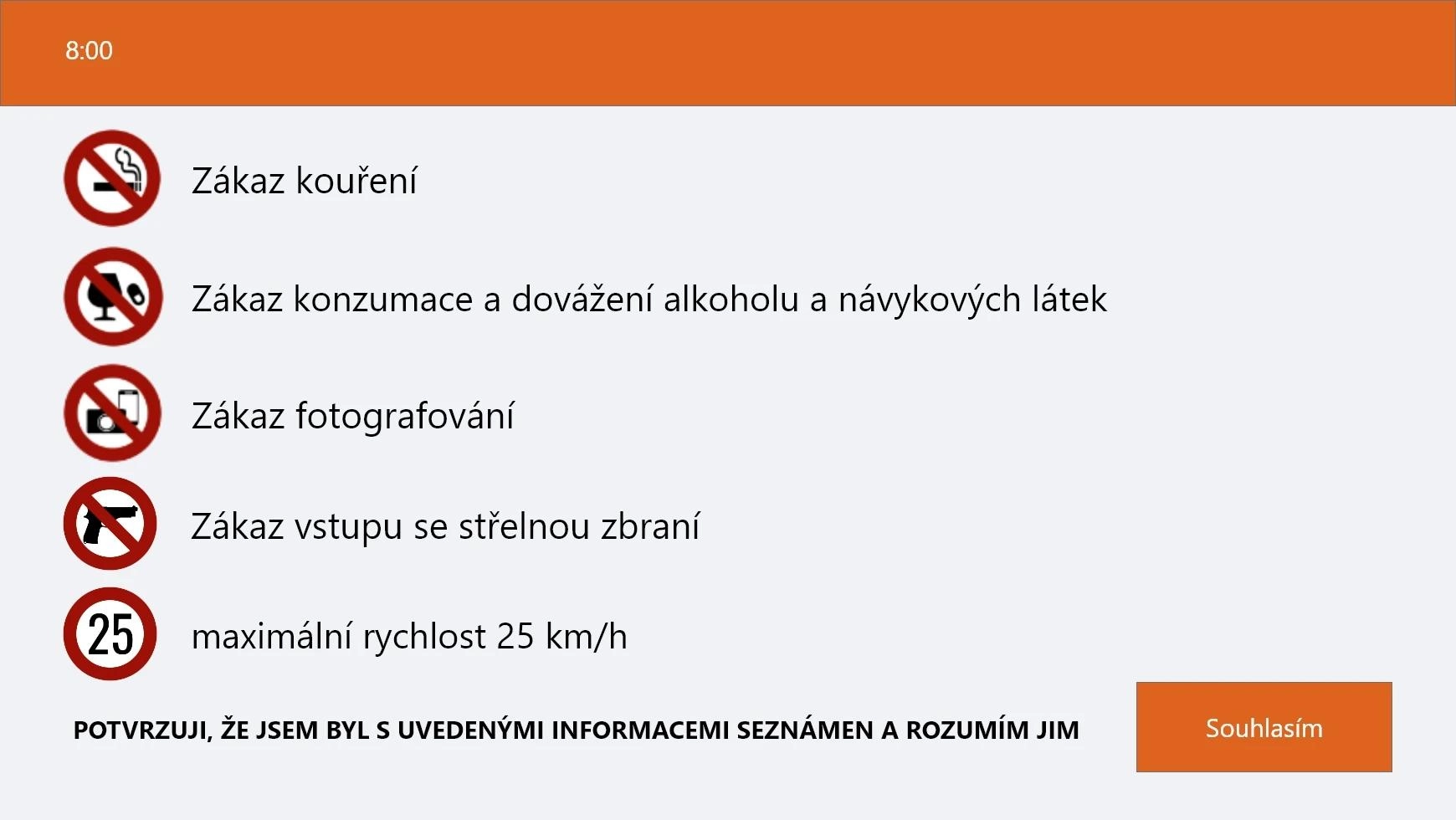

Registration also usually includes driver familiarisation and training in terms of occupational health and safety and compliance with the rules inside the premises.

Additional functions of registration can be, for example, scanning of documents, identification of the driver with a document, printing of one-time entry cards...

Single registration can be done in the following ways.

Self-service kiosk: A highly intuitive interface in up to 16 languages gives drivers an easy and quick way to register with the system. This also reduces staff contact with the driver, saving time and staff costs.

Automatic based on license plate recognition:

Automatic based on license plate recognition only:

For selected types of transport and vetted carriers, automatic registration can take place based on accurate booking/booking of the transport. All necessary registration data is used from the time slot management. Due to the speed of such registration, this type of registration is particularly popular for material transports between plants or the system operator's own vehicles.

Reception/doorman: If contact with the driver is necessary before the actual registration, for example in cases of vehicle or driver checks or entry into secure areas, registration can be performed by an operator on a PC or even on a tablet.

Mobile app: Last but not least, there is also the option of a mobile app for drivers where they are able to complete the registration without leaving the vehicle, this is particularly useful in cases of very frequent repeated visits to the premises by the same drivers.

Check-in

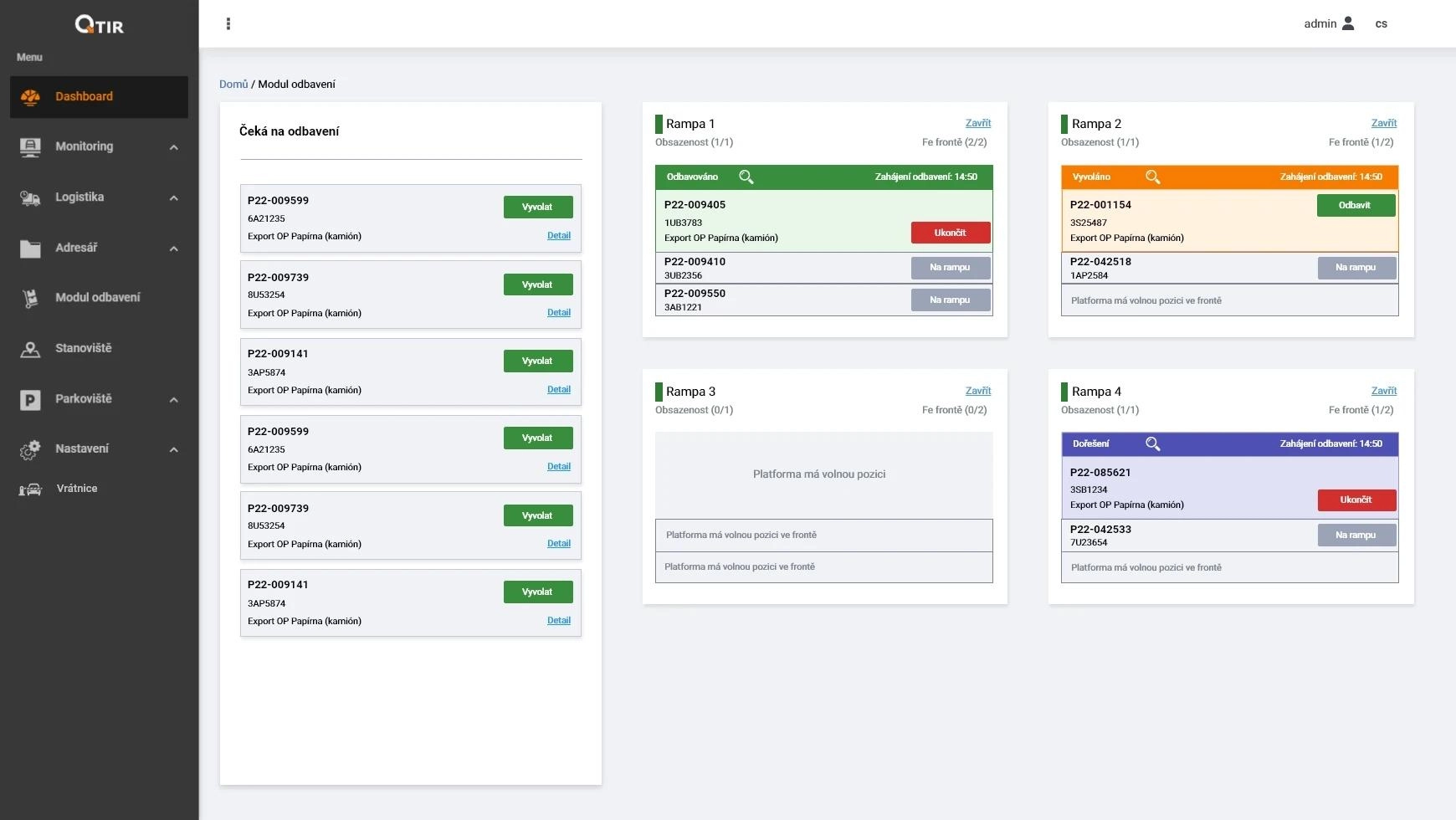

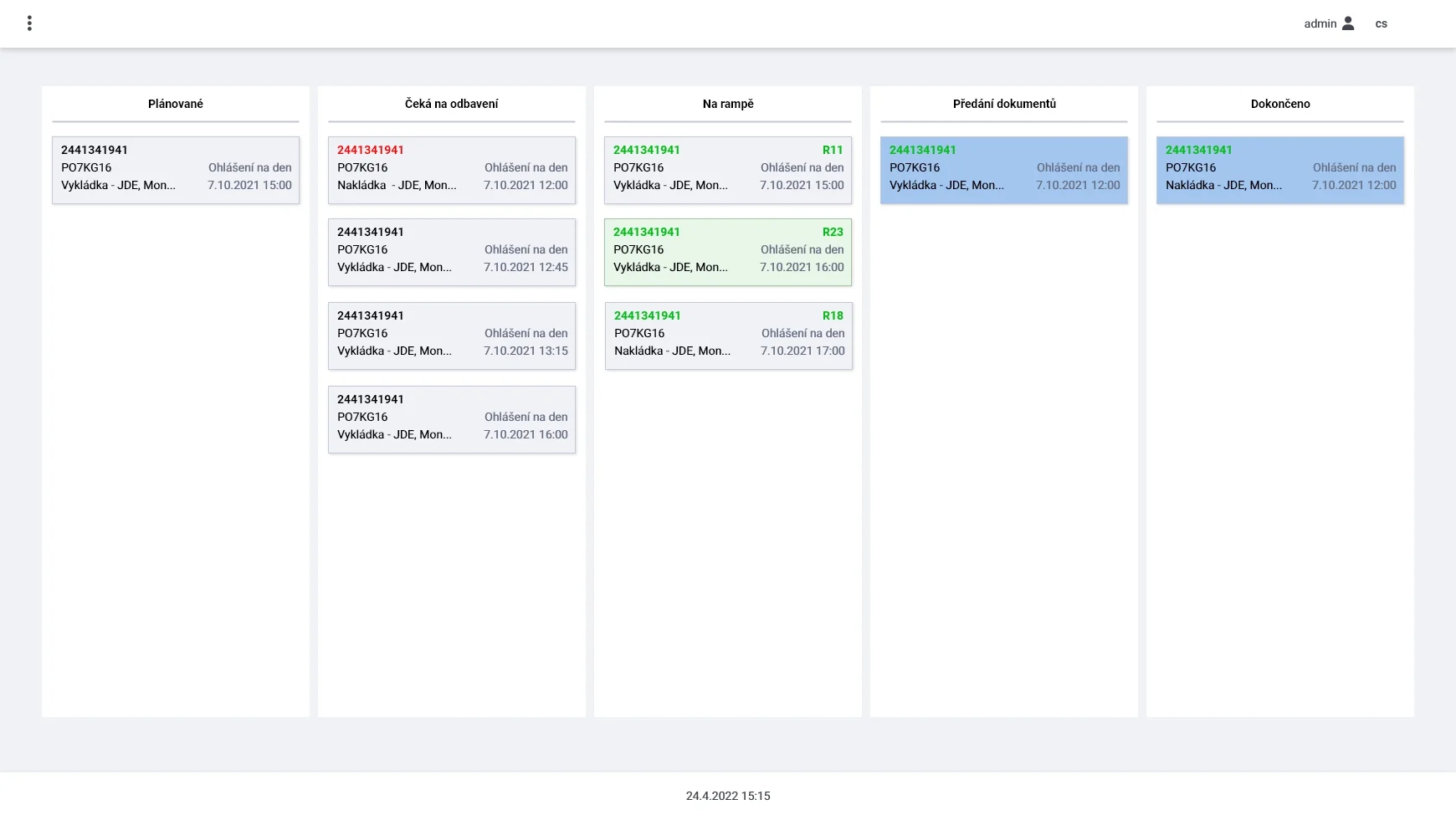

Once a shipment has been registered, it immediately appears in the QTIR system in the clearance module, in the logistics module, on the overview screens and from then on its status is constantly updated online.

This way, all staff, from logisticians to handlers, always have an up-to-date overview of all vehicles ready for check-in with all the necessary information.

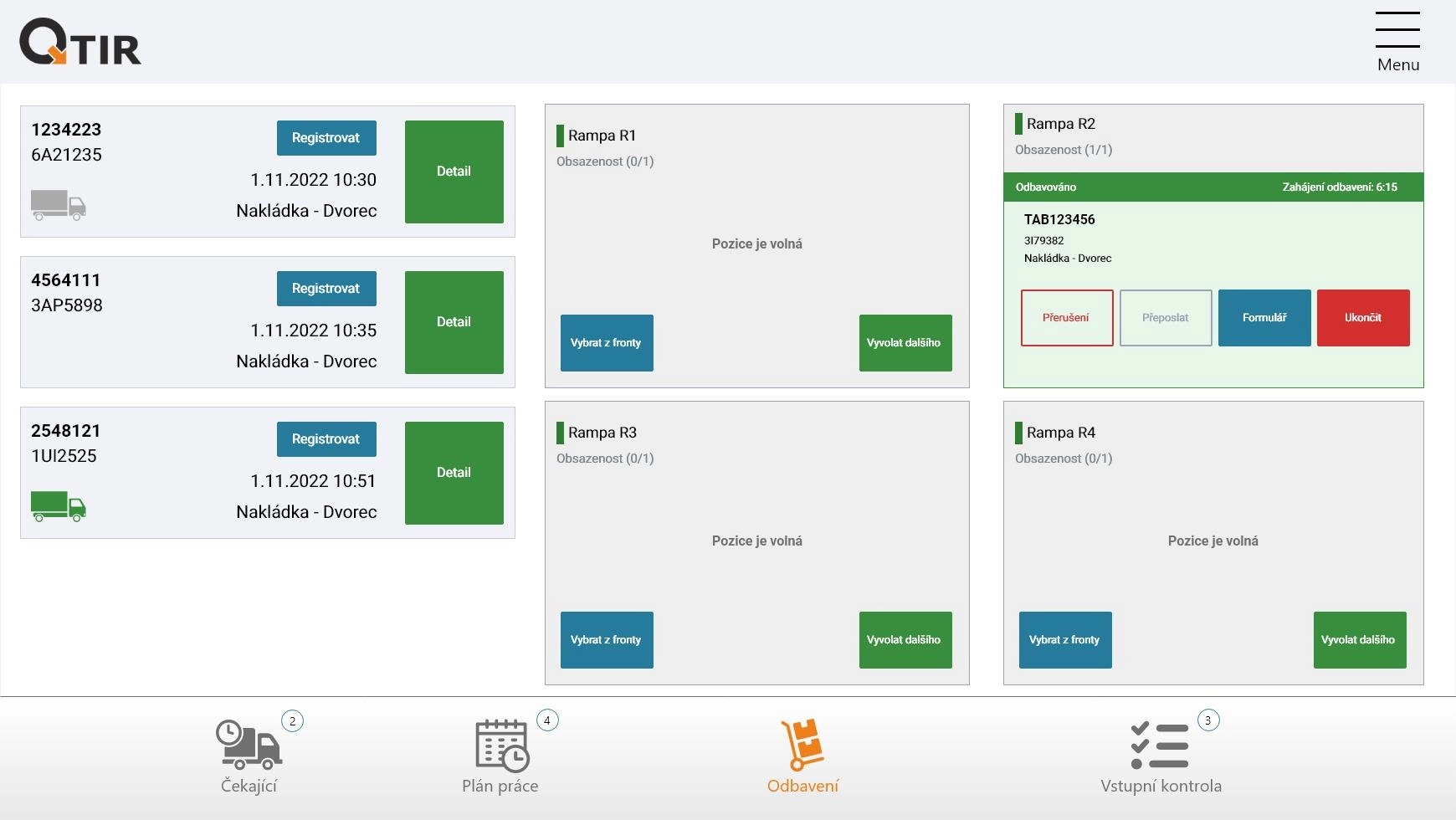

The QTIR system allows the logistics staff in the control centre as well as the individual handlers at specific check-in positions, ramps... to call up transports to meet the exact requirements of the specific operation.

When the vehicle is called to the selected check-in position, this information and other instructions are sent to the driver via SMS to the phone number entered during registration or to the driver's mobile application. Furthermore, this information is displayed on the call-up and navigation large-area displays located, for example, at the waiting car park, the entrance to the premises... In addition to contacting the driver, the driver is also granted permission to enter the premises and the possibility of further work with the transport as part of the actual clearance (loading/unloading).

During the clearance process we monitor the exact start and end time of the handling, we allow the handler to enter additional information on the transport, take photo documentation of the cargo and its securing...

Check-in is again enabled via a variety of devices, from a regular work computer, to a touchscreen kiosk with the ability to log in with an employee card, for example, to the very popular mobile device in the form of a phone or tablet.

These mobile devices can also be incorporated on forklifts, so the handler does all the paperwork within the forklift and doesn't waste time moving around the hall to PCs and the like. The mobile devices also make it very easy to take photo documentation, or to fill in various checklists for inspections and so on.

Entry and exit from the premises and controls

From the point of view of the yard management system, it is of course also very important to deal with the entrance and exit of the site. Entry and exit gates are incorporated into the check-in process based on the specific layout of the site, whether, for example, it has an outdoor parking lot and vehicles are only allowed into the site when called for check-in, or whether, on the contrary, all vehicles should be allowed into the site in the holding lot as soon as possible after arrival to avoid blocking traffic on public roads, etc.

Gateways are equipped with various HW equipment according to the requirements, typical are of course barriers, traffic lights, cameras with recognition of registration marks, overview cameras but they can also be RFID readers, QR / BAR code readers, navigation displays, scales...

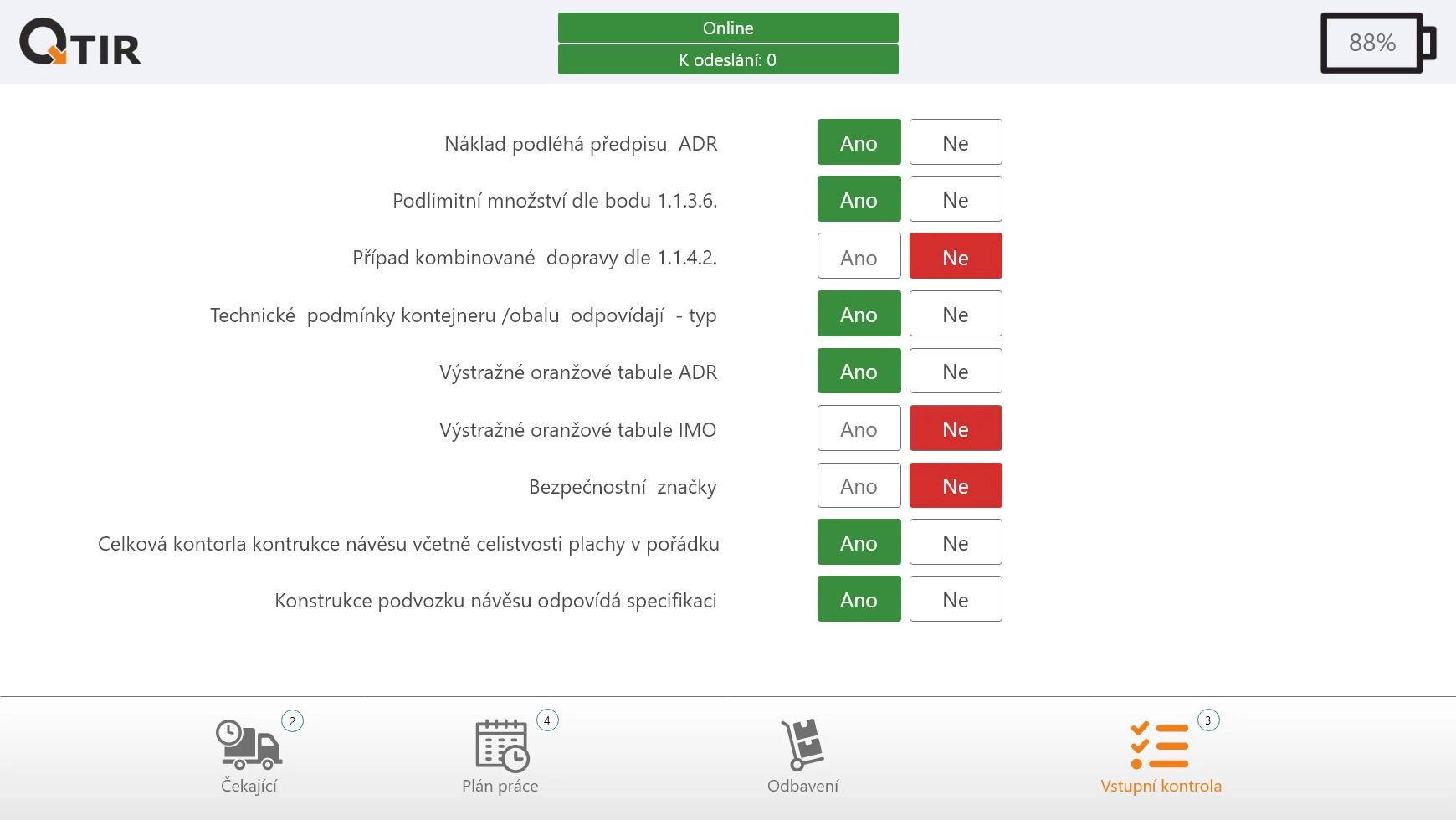

Very often we also deal with various security checklists at service gates, when the security guards check the driver and the vehicle according to individual points and record the course of the check in a mobile device.

Different entry and exit rules may be required for each type of transport after that. For example, material supply vehicles may enter on an RFID card and will be weighed each time, while dispatch vehicles will only enter on a registration tag and will be given a security checklist.

In addition to the registered transports themselves, the QTIR system allows other vehicle categories to be handled, such as employee and officer vehicles, visitor vehicles, service and municipal vehicles... For each category, rules for entry and exit can be set, such as regular or random checks...

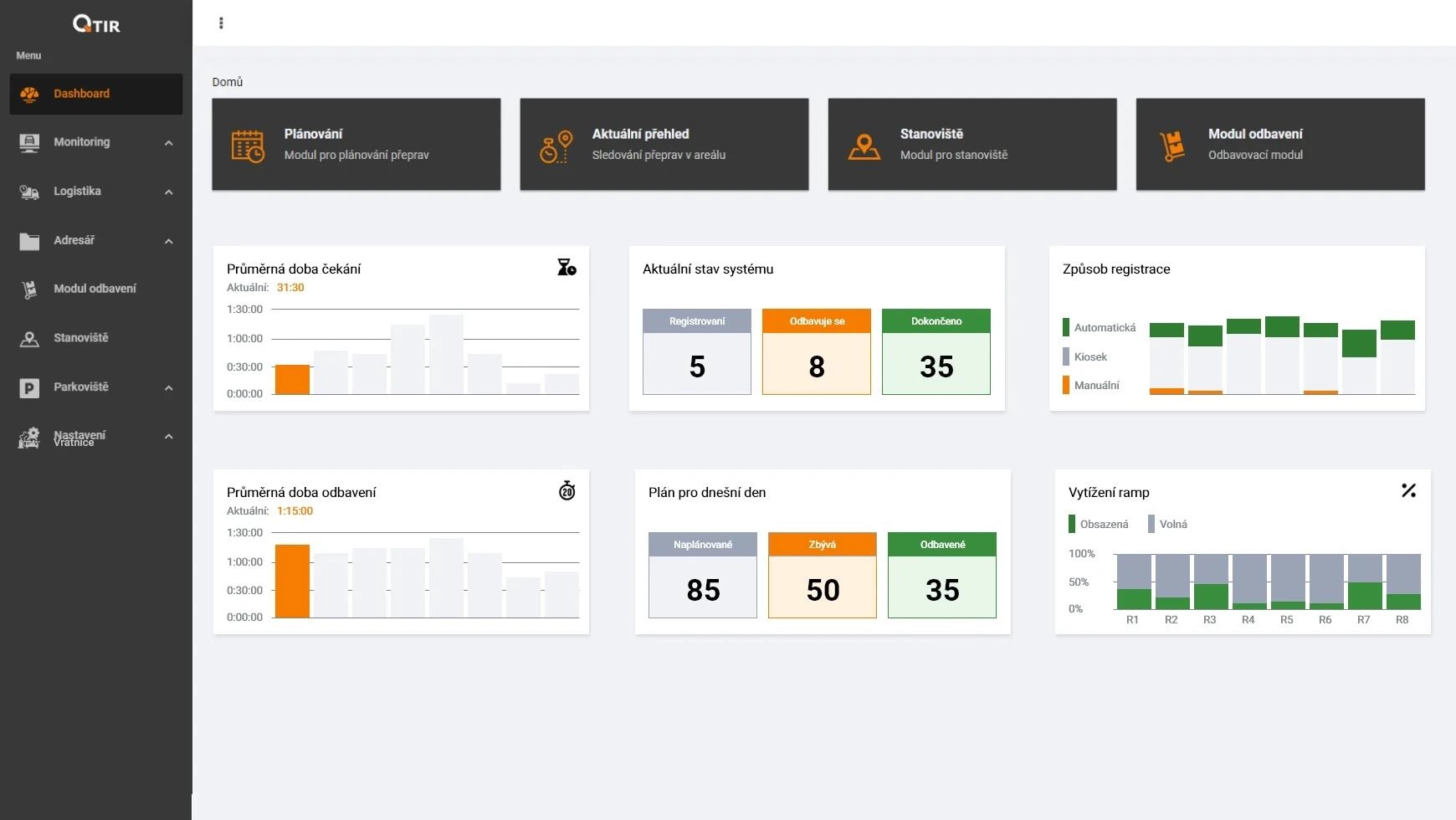

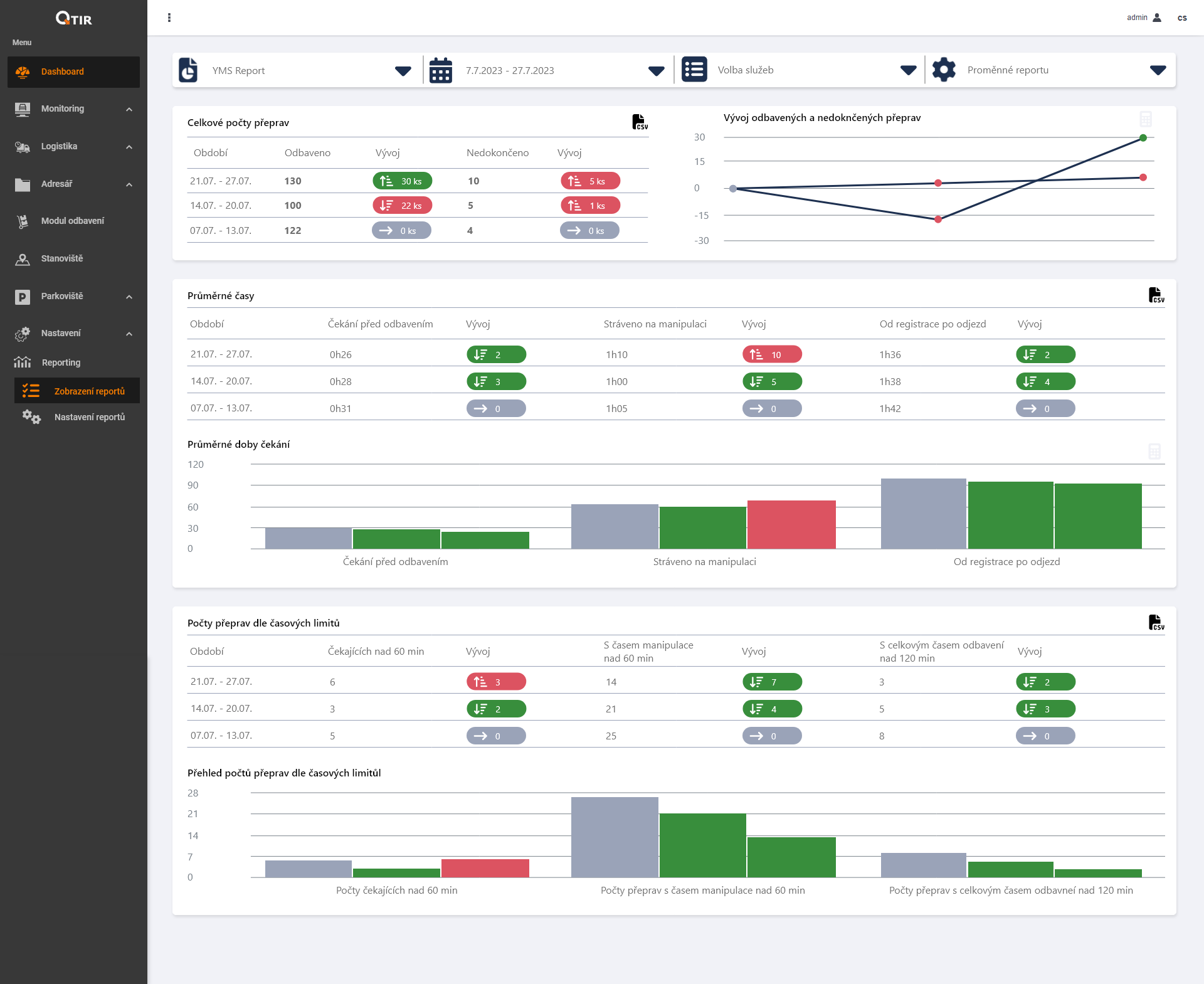

Monitoring, report

The Yard Management System provides an up-to-date overview of all shipments, their status, where they are, how long each operation has been in progress and a wealth of other important information that is essential for monitoring and managing loading and unloading operations. This information is available to all staff working with the system, in addition to the popular 'overview screens' located, for example, in dispatch centres, warehouses or directly in the offices of the handlers.

In order to evaluate and optimize operations, access to accurate data over the past periods is essential. This is provided by our reporting module, which quickly and clearly provides the most important data on the progress of the clearance process and also provides a trend for each value in comparison with the previous period. These reports are available to users directly in the QTir application, but it is also possible to set up regular email reports to be sent to, for example, managers who do not normally need to work with the system but need the data.